Metal-Free Ceramic Implant Technology is currently the fastest-growing and most innovative areas in dentistry. Intensive research and ongoing development, mean that zirconia implants are now ready to be taken seriously as an alternative to titanium implants for replacing missing teeth. Dentalpoint with its ZERAMEX® brand is a pioneer in “white implants”. In this interview with Ceramic Implants Magazine, Philip Bolleter, Head of the Technical Department, and Adrian Hunn, Head of Marketing and Sales, discuss the current state of ceramic implants.

Adrian Hunn has been a manager at ZERAMEX® since 2018 and is now in charge of marketing and sales. He has extensive international experience in senior management positions in sales and marketing.

Philip Bolleter was Head of Research and Development when Dentalpoint was first established. He is now in charge of the technical department of the company. He is also one of the brains behind the development of Dentalpoint’s groundbreaking ZERAMEX® technology.

Mr. Hunn, what impressions did you take away with you from the 2019 International Dental Show?

Hunn: Two core topics are clearly the center of interest for all suppliers on the market: digitalisation and new materials. Many suppliers have jumped on the bandwagon with ceramic implants and now include at least one type of ceramic implants in their portfolio. Naturally, we are very pleased about that. It indicates that we are on the right track and in which direction the trend is going. From day one, we have been uniquely focused on ceramic implants and the wisdom of this focus is now being confirmed. The second major topic, is digitalisation and we do not just want to fill gaps there, we will be at the forefront in 2019 with product development and innovation.

What makes ZERAMEX® different to other ceramic implant manufacturers?

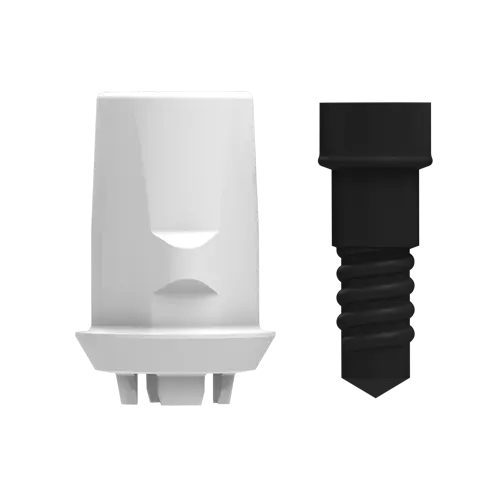

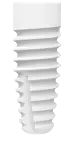

Bolleter: The main difference is that we now have 12 years of experience in developing and processing ceramic implants. ZERAMEX® has dedicated itself to ceramics and metal-free systems and has concentrated exclusively on these. Unlike other manufacturers, we only use sintered and BIO-HIP alumina-toughened zirconia for manufacturing our implants. With the manufacturing processes developed and completed in-house, it is possible to guarantee the maximum strength and precision required. We successfully launched the robust metal-free, carbon fiber VICARBO connecting screw more than 5 years ago. These developments and our many years of experience are what set us apart from other ceramic implant systems.

Will ceramics replace titanium implants in the future?

Hunn: What we are seeing right now is a massive increase in demand from patients for metal-free implants. More and more patients want natural and biocompatible products and are asking their dentists about alternatives to titanium implants. Of course, this puts pressure on dentists to offer both titanium and ceramic implants. So, if they do not want to lose patients, they will be forced to offer ceramic implants as well. According to market studies, the market share of ceramic implants is currently about 3 to 5 percent. The share is predicted to rise to 24 per cent by 2022. For us, this means that above-average growth with ceramic implants is possible in such a quickly growing market.

Do you still hear about ceramic implants breaking?

Hunn: Some dentists still refer to the Tübingen implants, but this is much rarer now. Most dentists are very well informed and are aware that the materials used are not the same as 30 years ago. Discussions with professors from various universities in Germany and Switzerland have confirmed that there is no longer any question about whether our implants will break or can successfully osseointegrate at the implantation site. We have the same osseointegration success rates as leading titanium implants, and therefore, this is no longer an issue. The development stage to qualify the fact that we achieve osseointegration of ZERAMEX® implants has been completed. For this reason, we are now focusing on prostheses and esthetics and have made advances in this area. We will be able to present some further innovations later this year.

Can any patient who needs tooth prostheses be treated with ZERAMEX®?

Bolleter: Any conventional treatment for single tooth or bridges can be implemented with ZERAMEX® ceramic implants. Along with the usual contra-indications for the patient, there are also certain limitations in relation to reduced diameters or special abutments. But generally speaking, all options are possible. We will soon be launching the new screw-retained LOCATOR1 (Zest Dental Solutions) as well, and this will also make metal-free hybrid treatment possible in edentulous jaws.

What can customers expect from ZERAMEX® in 2019, and what innovations can the European industry look forward to?

Bolleter: Most innovations are happening on the digital side, where we will be introducing the full integration of the digital workflow. The workflow for digital impression taking with an intraoral scanner from the more recent ZERAMEX® XT system has already been available since March in Europe. The CAD libraries for exocad and 3Shape are now available for use. Fully individualised abutments or monolithic zirconia crowns will also be available later in the year. ZERAMEX® has established the new digital solutions department, which will be rolled out over the next few months for dentists, dental technicians and laboratories for optimal support with digital treatment. It will provide dental technicians with a comprehensive service package which they can use to send in data and in return receive a complete treatment plan, with little processing time required. In addition, the service center is on hand to offer advice to dentists by hotline and email. As for other innovations, there is the new metal-free LOCATOR. Also, a reduced diameter is going to be introduced for the ZERAMEX® XT system in autumn. There are more innovations and surprises in the pipeline, but we are keeping them under wraps for now.

Hunn: I would also like to add that, in addition to the innovations we have mentioned so far, there is going to be a revised ZERAMEX® brand image. At the end of the year, we will present our innovations in a roadshow to all interested parties, and I am really looking forward to that.

What advice would you give to dentists who are uncertain about ceramic implants?

Hunn: I would advise them to ask their colleagues about their experiences and which systems they can recommend. This often leads to a good exchange of important and interesting information. Of course, they always have the opportunity to contact us directly if they want, for example, to arrange a commitment-free test surgery. Our experienced specialist advisers are available to give practitioners advice and will also support them with dental procedures if needed. Every employee in our company thinks ceramic and can provide professional help and answer many questions in that regard.

to the left Philip Bolleter (Head of the Technical Department at Dentalpoint)

to the right Adrian Hunn (Head of Marketing and Sales at Dentalpoint)

Contact

Want to know more about Zeramex?

Email us at mfoley@zeramexusa.com with your contact details and we will get in touch with you!

ZERAMEX BROCHURE

Click here to download the Zeramex sales brochure

Comments are closed.