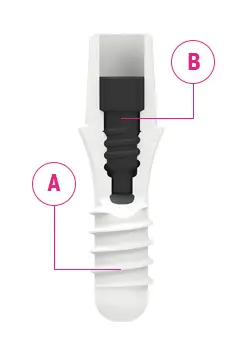

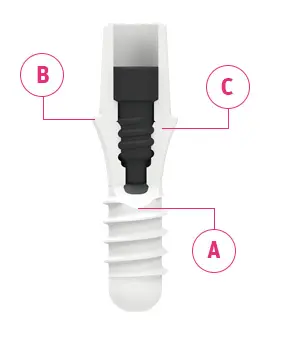

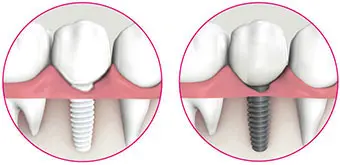

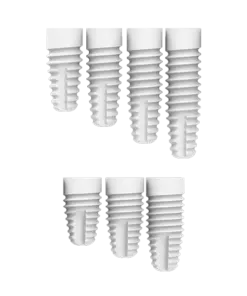

100% metal-free ceramic implants

Very close to the natural tooth root aesthetically and in functionality.

10 years of Swiss experience

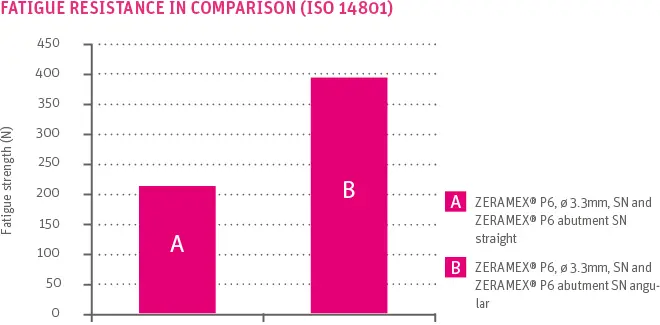

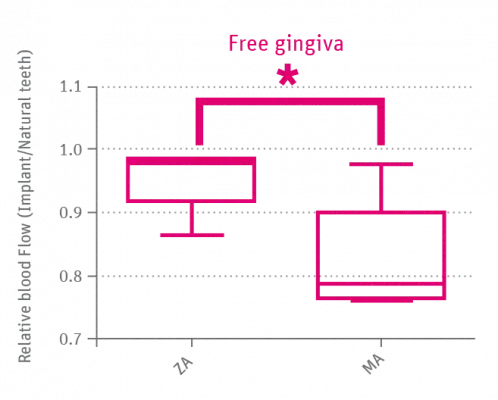

The advantages of ZERAMEX® ceramic implants have been

established in several studies.

established in several studies.

A high success rate, sustained satisfaction

Offer your patients a better quality of life with metal-free

ceramic implants from ZERAMEX®.

ceramic implants from ZERAMEX®.

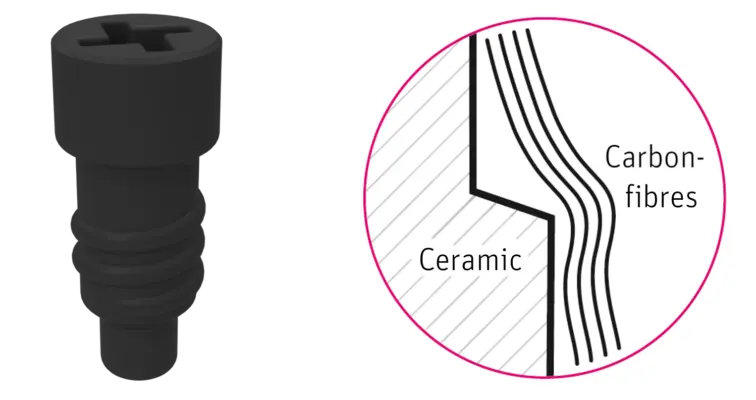

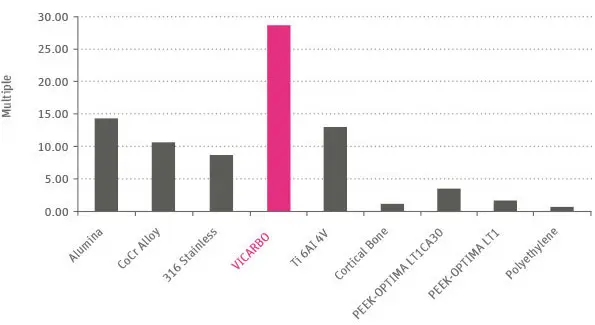

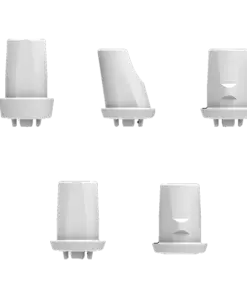

Flexibility and compatibility

Ceramic implants from ZERAMEX® have many

advantages over conventional dental implants.

advantages over conventional dental implants.