Read more about Vicarbo Technology:

Interview F&E Pascal Wettstein – Vicarbo Technology

Carbon – established in dental implantology

Pascal Wettstein is an experienced R & D engineer with a profound background in materials science. He has been with Dentalpoint since 2014 and part of the great pioneering work. Before joining Dentalpoint, Pascal Wettstein worked for several years as an engineer in the R & D department of renowned Swiss medtech companies.

Mr. Wettstein, ceramic implants are enjoying an upswing in the dental industry. With a current market share of 2-3%, it is predicted that ceramic implant systems will enjoy a market share of up to 25% by 2022. Dentalpoint is a pioneer in this upswing. With what innovation has the ZERAMEX® brand revolutionized dental implantology?

PWE: Historically, in the past, people had a choice between a one-piece and a two-piece bonded implant system, and that’s where ZERAMEX® started. However, we quickly realized that, for reasons of prosthetic flexibility, a two-prosthetic solution is needed. In implantology with titanium implants, virtually no one-piece systems are used anymore, as these are not easy to supply. So our task was clear that even in metal-free implantology you have to offer a system that is reversibly screwed. We were the first to launch a 100% metal-free and two-piece ceramic implant system that is reversibly screwed. This is the great innovation of Zeramex.

The ZERAMEX® systems are known for Vicarbo, a carbon fiber ceramic technology. Why did you choose the material carbon fiber at ZERAMEX®? What are the properties of this Vicarbo technology?

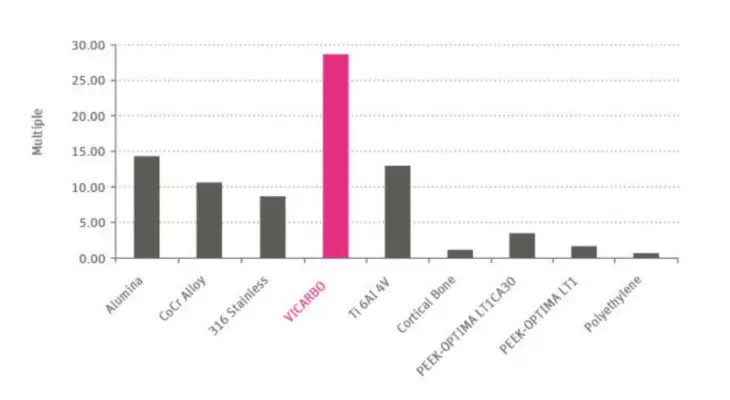

PWE: Fiber composites and especially carbon fiber composites have very special material properties. They have a very high tensile strength (about twice as high as e.g. titanium grade V) and stiffness, they are chemically resistant and they are anisotropic due to the fibers. This means that in the fiber direction you have different properties than transversely. This can be taken advantage of by controlling the fiber course or placing it in the main load direction(s).

A classic example is the bicycle fork made of a carbon fiber composite: it is designed to react elastically to longitudinal loads so that it can optimally cushion impacts, etc. Cross or on torsion it is very stiff, as this massively improves the handling of the bike. With an aluminium fork, it is not possible to control the properties in this mass, as this is an isotropic material (the properties are broadly the same in all directions).

These excellent mechanical properties, combined with low weight, have led to this material being established in a wide range of high-tech industries such as aviation (A380 and Boeing 787), aerospace and racing.

We also make use of the above-mentioned properties. In this way, we build the screw through the process control in such a way that the main fiber curve lies in such a way that it can withstand high mechanical loads on torsion and pull. The combination of a relatively soft screw with the very hard ceramic also allows us to produce the screw in a slight excess. The screw then nestles in the ceramic thread. This results in a sealing effect. The matrix material in our case is PEEK, which has a long tradition in medical technology.