Accuracy of Torque Control – Devices in Implant Dentistry – An In-Vitro Study

Varun Goyal1, BS, Rafael Delgado-Ruiz2, DDS, MSc, PhD, Kenneth S. Kurtz2, DDS, FACP, Georgios E. Romanos1, DDS, PhD, Prof Dr med dent

1Dept. of Periodontology and 2Dept. of Prosthodontics/Digital Technology, School of Dental Medicine, Stony Brook University, Stony Brook, NY

Introduction

When placing implants, the use of precise torque values is a prerequisite to achieving the correct preload, which plays a vital role in reducing screw loosening. In addition, accurate values can prevent excessive torque, which may conduce to deformation and fractures of the prosthetic screw, and other components of the Implant Abutment (I/A) connection

Objective

Spring-based conventional torque wrenches and torque controllers are differently operated devices that may be used in Implant Dentistry to achieve desired torque levels. The objective of this in-vitro study was to evaluate the precision of these different torque-control systems used within Implant Prosthodontics.

Methods

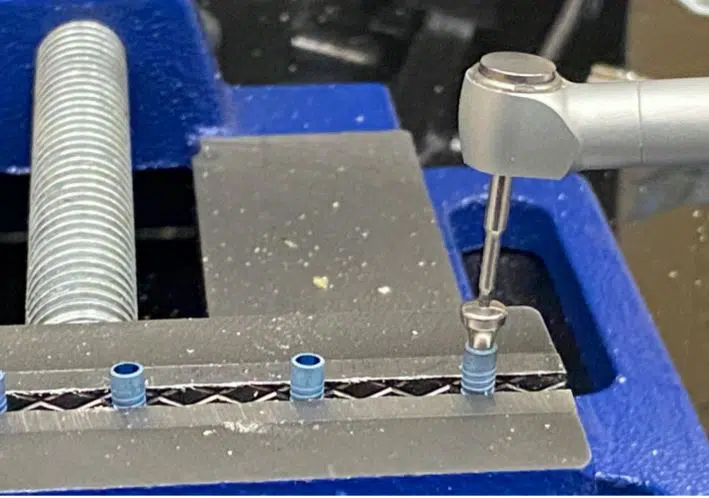

Two implant systems with different Implant-Abutment connections were evaluated. Group A (Ankylos, Dentsply-Sirona) and group B (Bone Level, Straumann) implants were immobilized securely with an Irwin laboratory vise. Three torque control devices were compared. Conventional torque wrenches (spring-based) for A- and B implants were used to tighten healing abutments (n = 20) to pre determined values of 15 Ncm. The removal torque was assessed with a digital torquemeter – DT, CEDAR DID-4A. In a second round, healing abutments were tightened using a pre-calibrated torque control – CTC, Anthogyr – with respective drivers (Fig. 1). The DT was used to remove the healing abutments (Fig. 2). Values were recorded. Descriptive statistics, mean, and standard deviations were used to present the data. ANOVA analysis was completed to evaluate differences between groups, and post-hoc test was used to confirm multiple comparisons of differences between means. Significance was set as p<0.05.

Results

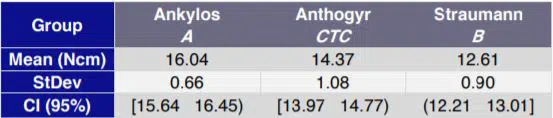

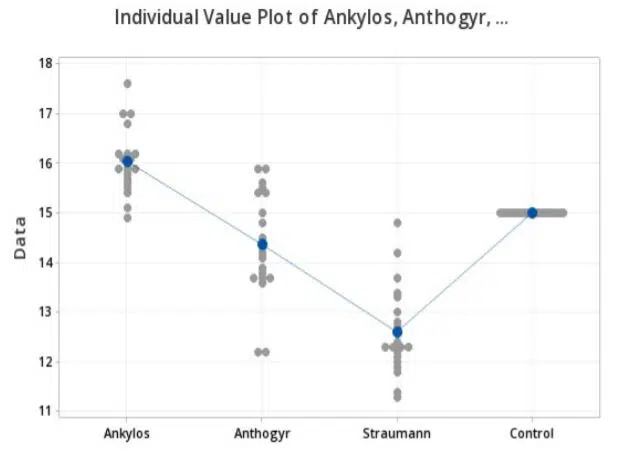

The removal torque utilizing theDT for A-implants was 16.04 (± 0.66) and for B-implants 12.61 (± 0.90) Ncm (Table 1). The closest values to the DT were achieved by the CTC device (p < 0.05), which was 14.37 Ncm (Table 1). The standard deviation for the CTC, however, was the largest (Graph 1).

Clinical Implication: Over and under estimation of the torque values are present in all of the evaluated systems (Graph 1).

This may be due to improper usage, sterilization damage , and lack of re-calibration, conducing to deficiency of I/A preload or fracture of the prosthetic screw.

Conclusion

Within the limitations of this study, inexact torque values were represented using the conventional torque wrenches and pre-calibrated torque controller. More calibration is required to control risks in Implant Prosthodontics.

References

Standlee JP, Caputo AA, Chwu MY, Sun TT. Accuracy of mechanical torque-limiting devices. Int J Oral Maxillofac Implants. 2002;17(2):220-4. Yilmaz B, L’Homme-Langlois E, Beck FM, McGlumphy E. Accuracy of mechanical torque-limiting devices for dental implants after clinical service. J Prosthet Dent. 2015;114(3):378-82.

This poster by Varun Goyal won the ACP 51st Annual Session 2021

The virtual event by The American College of Prosthodontists was held last OCTOBER 26-30, 2021. There were 57 posters, 54 videos, 2 topics, 154 authors and 62 institutions.

In the videoclip below, ACP 51st Annual Session 2021 ePoster winner, Varun Goyal, talks about Anthogyr’s Torq Control.